2.1 Technical background

The exhaust gas emitted during the viscose fiber production process contains carbon disulfide and hydrogen sulfide. If it is directly discharged into the atmosphere, it will form acid rain and affect the quality of the local environment. This hazard has been increasingly recognized by people, and the treatment of exhaust gas is also increasing. It has been paid attention to in recent years, so that various waste gas treatment technologies have been developed in order to remove harmful substances in the waste gas with lower equipment investment, less input of raw and auxiliary materials and operating costs, and make it repeatable Raw materials used.

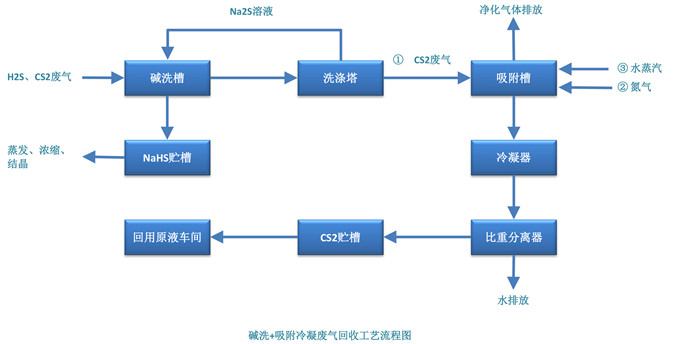

2.2 Process flow

2.3 Process description

After the process exhaust gas is collected, it enters the exhaust gas treatment device. First, it passes through the alkali washing tank to convert more than 97% of H2S in the exhaust gas into NaHS. At this time, the concentration of unconverted H2S in the exhaust gas is below 100ppm. Then, the exhaust gas enters the scrubber and reacts further with NaOH , to generate Na2S solution. After the above alkali washing treatment, the concentration of H2S in the exhaust gas from the scrubber drops below 10ppm. At this time, the main component of the process exhaust gas is CS2, which enters the adsorption tank for further treatment. The CS2 in the exhaust gas is adsorbed by activated carbon in the adsorption tank, and when the CS2 adsorbed by the activated carbon is close to the saturated state, it will transfer to other tanks to continue working. Adsorption of CS2 to saturated adsorption tank is filled with nitrogen to replace the air, and then heated by steam to desorb CS2. After desorption, the steam containing CS2 is condensed into liquid CS2 through the condenser, and then the water is separated by the specific gravity separator to recover CS2. Enter the storage tank and continue to supply the yellowing use of the original solution workshop.

2.4 Product Features

This technology collects the CS2 and H2S waste gas discharged from viscose fiber production, and after washing, adsorption, condensation and separation, converts hydrogen sulfide gas in the waste gas into sodium hydrogen sulfide liquid, and converts carbon disulfide gas in the waste gas For carbon disulfide liquid. Carbon disulfide liquid can be directly used as raw material in the production of viscose fiber, and sodium hydrosulfide is widely used in industry.

2.5 Technical indicators

H2S removal rate 99.7%

The removal rate of CS2 is 97%

H2S emission concentration 13.6mg/m³

CS2 emission concentration 156.4mg/m³

The total S removal rate is 99.7%

2.6 Desorption method

Water vapor desorption, nitrogen desorption, vacuum desorption, nitrogen + vacuum desorption

2.7 Main Patents

200720008411.0 A device for recovering waste gas from viscose fiber production by alkali washing, adsorption and condensation

201220086345.X Viscose fiber dehydrogen sulfide absorption device

201320421795.4 A viscose fiber desulfurization recovery device